The most preferred special type of tools are flattening tools. Flattening on the sheet can be commonly carried out with 3 different tool types.

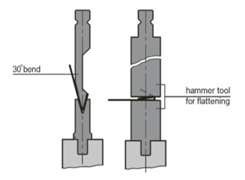

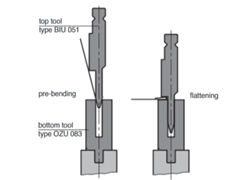

Two different tool sets are used for the first type flattening. The first set is used to bend the hemming area to a 30 degree angle. The second set smoothes the bending area and straightens the process.

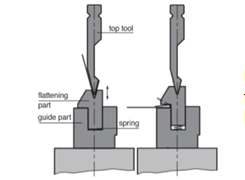

In the third type of hemming, a special spring bottom die is used for operation. The upper tool can be a standard tool 30 degrees or less. The most important criterion here is that the upper tool is able to withstand the hemming force.

A second set of hemming uses a single tool set. As shown in the figure, a 30 degree twist is carried out in the U-shaped bottom tool. Then hemming is done in the front part.

One of the most common problems encountered during the bending process is the marks left on the bending area of the tool. A protective cloth is used to minimize these marks. Wila protective cloth is made of kevlar material. In this way, it reduces the scarring by providing inter-metal support and can be used many times.