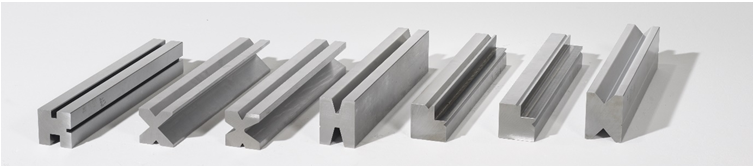

Different bottom tools may be preferred in accordance with the machine bottom holder. Most commonly used are T-shape dies and 4 sided dies. The suitable tool is determined in accordance with geometry of the bending project.

Both dies and top tools have 3 diffrent tool lengths. These are; 835 mm , 415mm and 835 mm sectionalized tools. Sectionalized upper tool has horn extensions on right and left sides.

Special Bending Tools

In projects that cannot be bended with standard tools, the suitable special tool can be determined by carrying out a project work. A standard tool can be modified to create a special tool or a new tool can be designed.

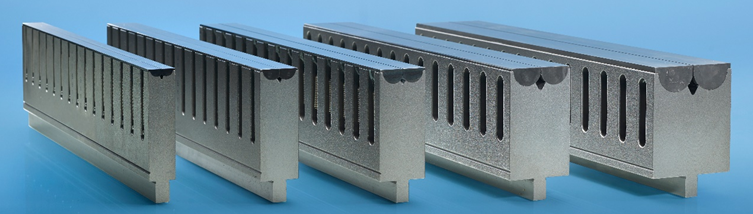

Additionaly, there are Unibend and Wingbend named customized dies. In these tools, v channels are movable to support the sheet during the bending process. This feature reduces bending marks. Also one of the biggest problem is making short flanges. Thanks to these customized tools, shorter sides of the sheet metal can be bended easily.