Full Automatic Tool Grinding Machine

Perfect Results in a Few Seconds with Automated Tool Hight Measurement

Ares TG-180 Full Automatic Tool Grinding Machine, has developed to give the best performance of punch and dies which you used in the punch machines. By virtue of grinding with Ares TG-180, we guarantee an increase in the service life of the tools, an improvement in the cutting quality of the punch machine and, as a result, an increase in the quality of your production.

You can easily grind common tool types such as Thick Turret, Murata Wiedemann (112-114-Marathon-Vulcan), Trumpf Type, Thin Turret of each brand by fixing on the magnetic table or on the chuck. Through its 0.005mm height adjustment accuracy, powerful coolant spraying device and easy operation, you can achieve smooth, rough and sharp surfaces in a short time. In your busy schedule, you don’t need to wait near the machine. When the operator starts the machine, at the top of the machine, signal light turns red (running) and when it finish the job it turns green (ready for next).

| Weight | 520 kg |

| Electric Usage | 380V/50Hz |

| Power | 3000 W |

| Engine RPM | 3000 RPM |

| Control Panel | 24 V |

| Wheel Diameter | Ø200 mm |

| Touch Screen | 10” |

| Chuck Maximum Diameter | Ø160 mm |

| Maximum Punch Height | 230 mm |

| Maximum Die Height | 230 mm |

| Minimum Chip Amount | 0,005 mm |

| Air Pressure | 6 Bar |

Use Your Punch Press Tools Longer!

In the machine, all electronic devices are first quality and runs with 24V for operator safety.

Front door is automated. After opening it you can put punches and dies on the chuck.

Be sure the parts fixed on the chuck by using an allen wrench.

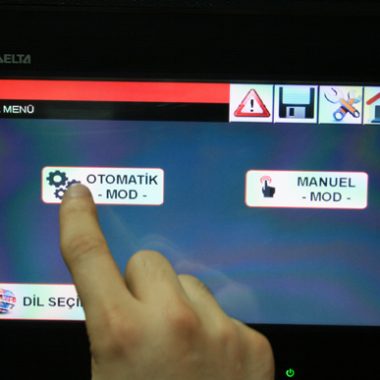

You can use existing tool parameters by choosing automatic mod on the LCD screen.

On the touch screen, enter grinding value of the tool.

You can change any parameter value from tool type selection screen , which suitable with your tool library

Now Everything is ready! When you start the machine, the height of the tool will be calculated by itself.

When it finish grinding, you can easily clean the surface of the tools by using the coolant sprayer (machine’s left side).

CBN Wheel for Excellent Results on Different Metal Surfaces

The MTG-160 grinder can be used not only for punch tools, but also on all metal planar surfaces where you need smooth surfaces. CBN (Cubic Boron Nitride), which is using in the machine’s grinding wheel, is the hardest material after diamond. It has high hardness and toughness values. Steady state with high temperatures makes it the best grinding precision on hardened and vanadium including steels To do this, it is enough to fix the planar molded parts and apparatus –up to 160mm in diameter- on the machine tables. The die/punch shims which are loaded upon long usage may lose the surface flatness as a result of adhesion and/or deformation of small metal parts. In this situation, you can fix the die/punch shim to magnetic table and provide the smooth surface by removing chips thinly. You can see the limits of the parts, which can be connected to table and chuck, in the table on the last page.